Advanced CNC Turning Solutions

Delivering highly accurate, repeatable, and cost-effective cylindrical components for global OEM and industrial markets. Specialized in multi-material high-speed turning.

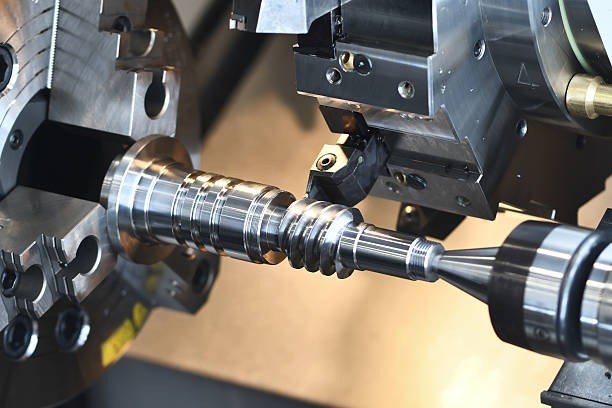

Precision Lathe Machining

CNC turning is a subtractive manufacturing process where a rotating workpiece is shaped by a stationary cutting tool. At Orange Group, we utilize high-speed fixed-head CNC lathes that achieve exceptional precision and high production efficiency.

Our turning services are ideal for parts requiring axial symmetry, precise internal/external threads, and complex rotational profiles. We handle batch sizes ranging from prototypes to million-piece serial orders.

Turning Capabilities

Technical Parameters

- Max Diameter 300mm

- Max Length 600mm

- Repeatability ± 0.01mm

- Spindle Speed Up to 6000 RPM

Common Turned Components

- • Precision Shafts

- • Bushings & Sleeves

- • Pins & Dowels

- • Spacers & Collars

- • Threaded Plugs

- • Valve Internals

- • Sensor Bodies

- • Housing Units

Multi-Material Turning Excellence

Choose Accuracy. Choose Scale.

Partner with Orange Group for precision CNC turned components manufactured to global standards and delivered worldwide.